RapiTrim-G-IR

SYSTEMS

RapiTrim-R-G

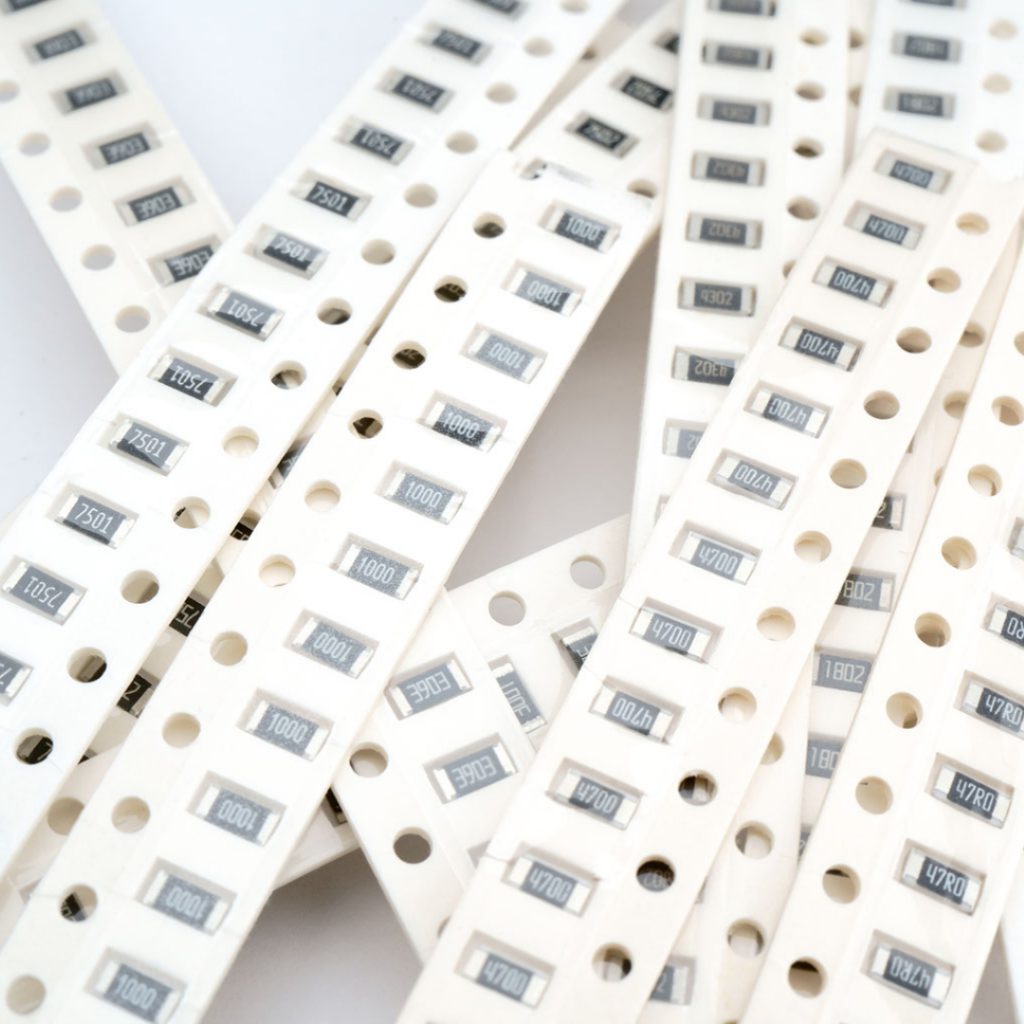

- Chip Resistor Trimming For Thin-Film

- Green (532 nm) Laser

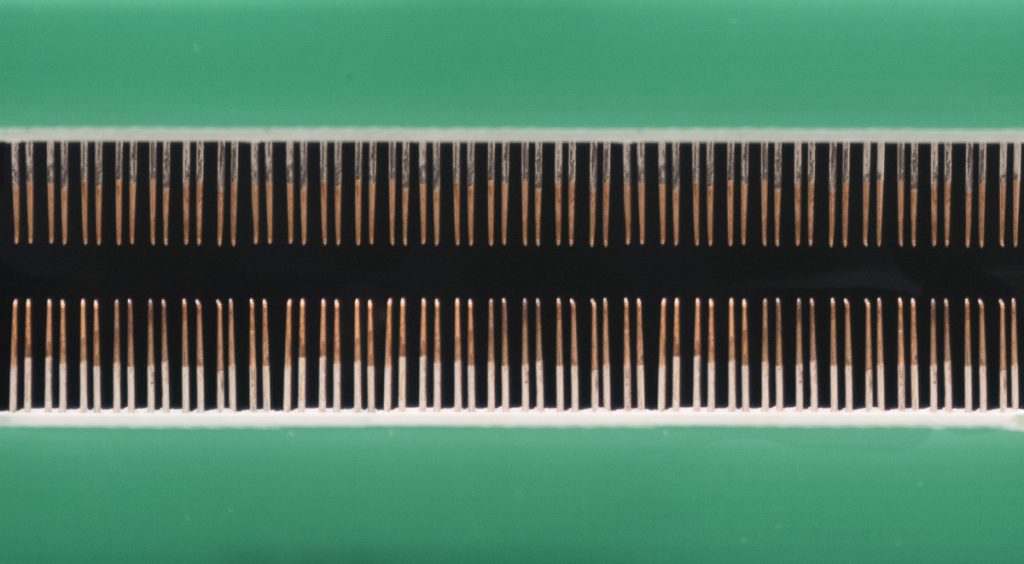

- Probe Card Measurement supports up to 512 pins

- Spot Size 8-25 µm

- Resistor Range: 0.1 Ω to 1 GΩ

RapiTrim-R Trimming System with Green (532nm) Laser for Thin Film Chip Resistors

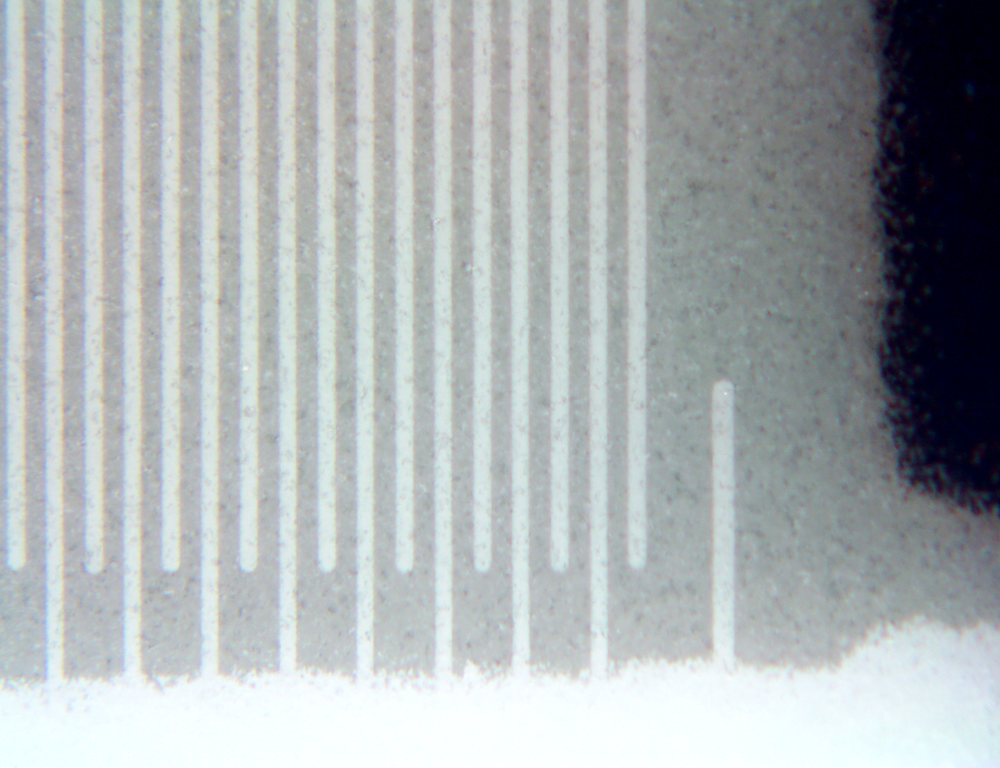

For thin film chip resistors, green lasers are typically chosen due to their smaller spot size, with the corresponding reduction in the kerf width and thermal effects. This results in an increase in the final resistor accuracy and repeatability.

Automatic XY and θ alignment is performed by XY stages and rotation adjustment using through the lens vision and automated planarization (both roll and pitch).

Features include:

- Automatic job setup

- Servo-controlled Z velocity and acceleration enables profiled motion trajectory control to improve probe tip placement and contact precision

- Automatic probe card cleaning and tip scrubbing

- Optional temperature-controlled chuck fixture.

- Probe card assembly is designed with lever-operated clamping for quick exchange of probe cards.

Capabilities

- Thin-film trimming on chip resistors.

- Designed for products down to the 0201 resistor size.

- Intuitive graphical Job Setup with automated DXF import and process sequence customization.

Contact PPI Systems

Flying probe operation, robotic load-to-unload, stack loader and PPI overview.

An intuitive graphical user interface that offers unmatched ease of use for both operators and process engineers.

Where efficient and intelligent solutions come to life in collaboration with our customers.

Designed for Next-Generation Chip Resistor Trim and Test

PPI provides proprietary measurement and trim control systems which measure actual resistance in real-time. Modern data acquisition, FPGA and DSP technology are used for real-time laser control with cut measurement data available as part of normal operation, speeding process optimization. The system provides four independent source-measure units, each capable of Kelvin measurement.

The system Trim Controller interfaces to external instrumentation for passive and active trim operations using standard LAN (LXI) and GPIB interface. All external instruments are controlled through the one RapiTrim-C user interface.

Advanced ProSys Control Software

ProSys software allows for automated file conversion and job generation and provides a graphic display of the job features and process status. All machine setup calibration controls, job and process settings, vision and process map, status and diagnostic information are accessible with a single click or tap on the intuitive touchscreen user interface. Process tools allow precise control over laser energy, bite size, cut geometries and trim limits. Custom trim sequences allow component processing to be tailored to a specific application using a sequence of sub-talks implemented in a user script.