Resources

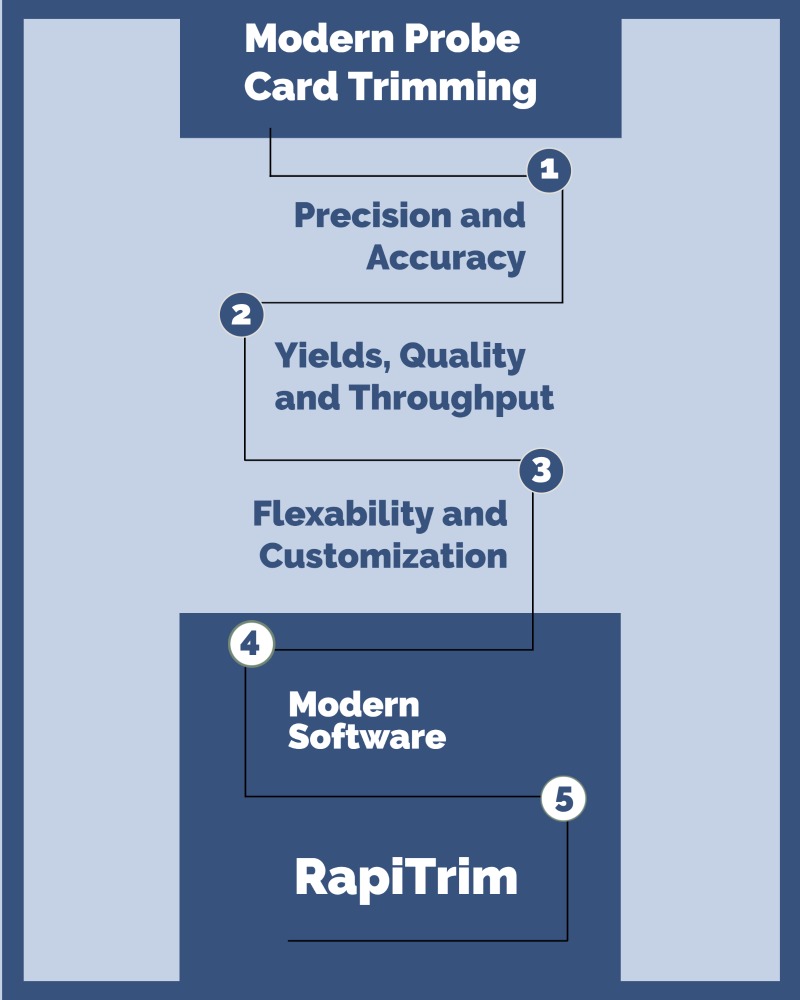

The Advantages of Modern Probe Card Laser Resistor Trimming Systems

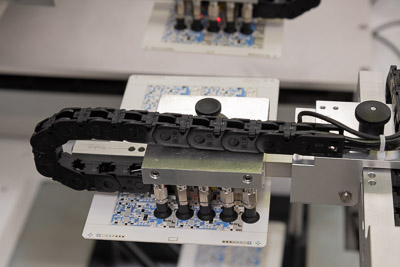

Next generation hardware and software designs provide significant performance and speed advantages when compared to older probe card trimming systems developed 30-40 years ago.