Systems

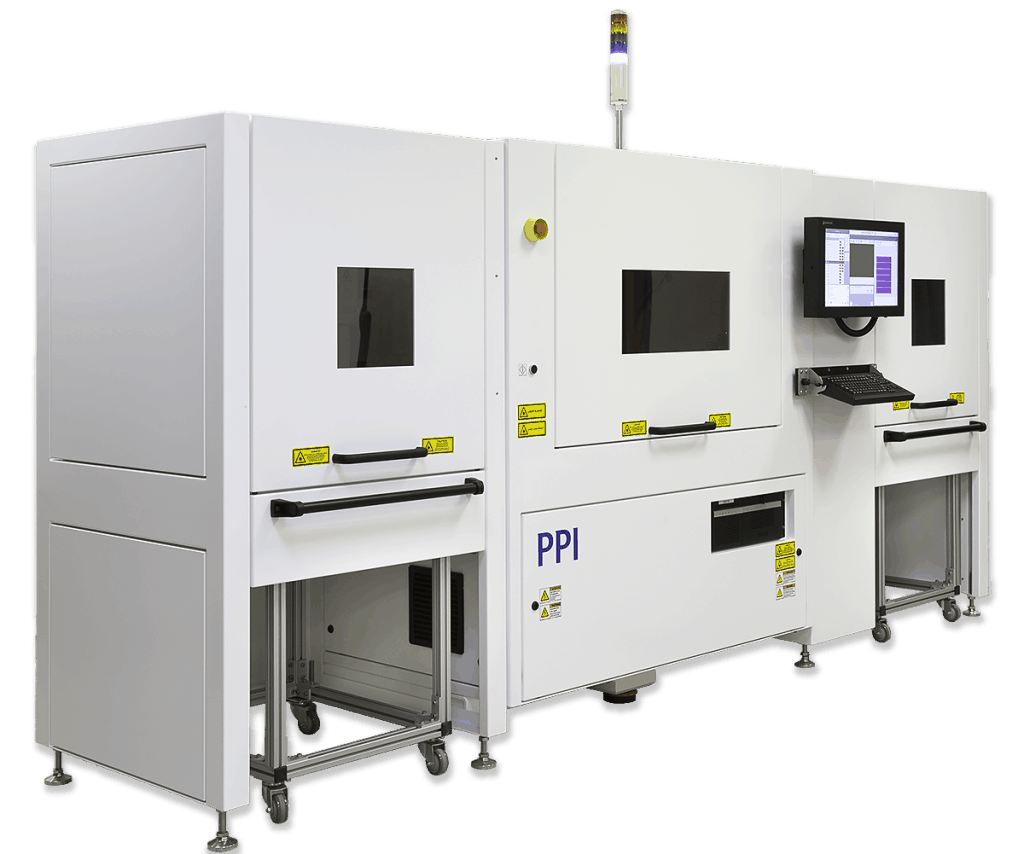

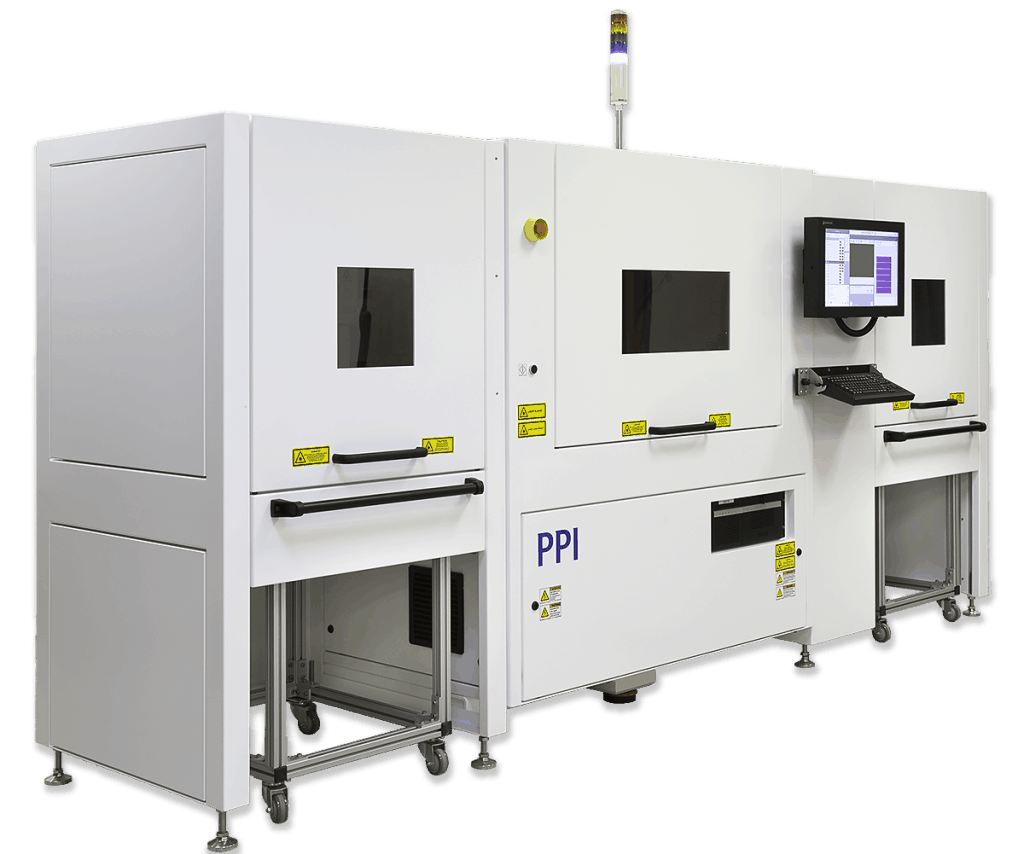

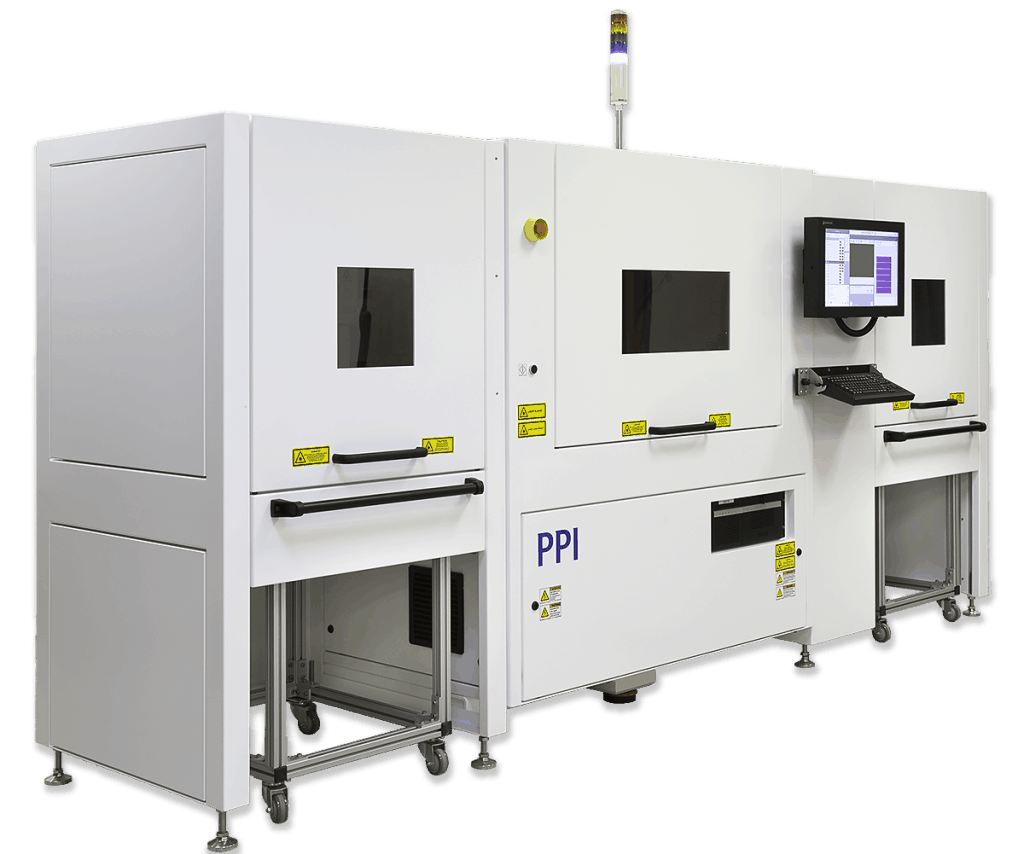

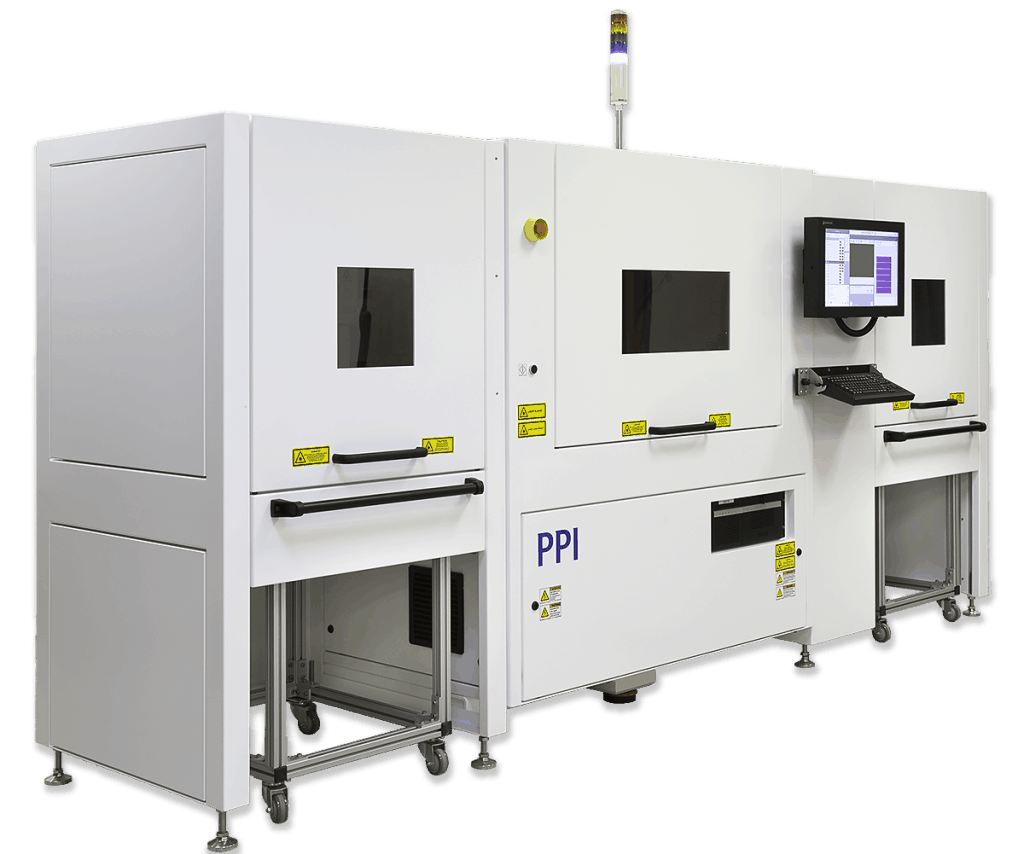

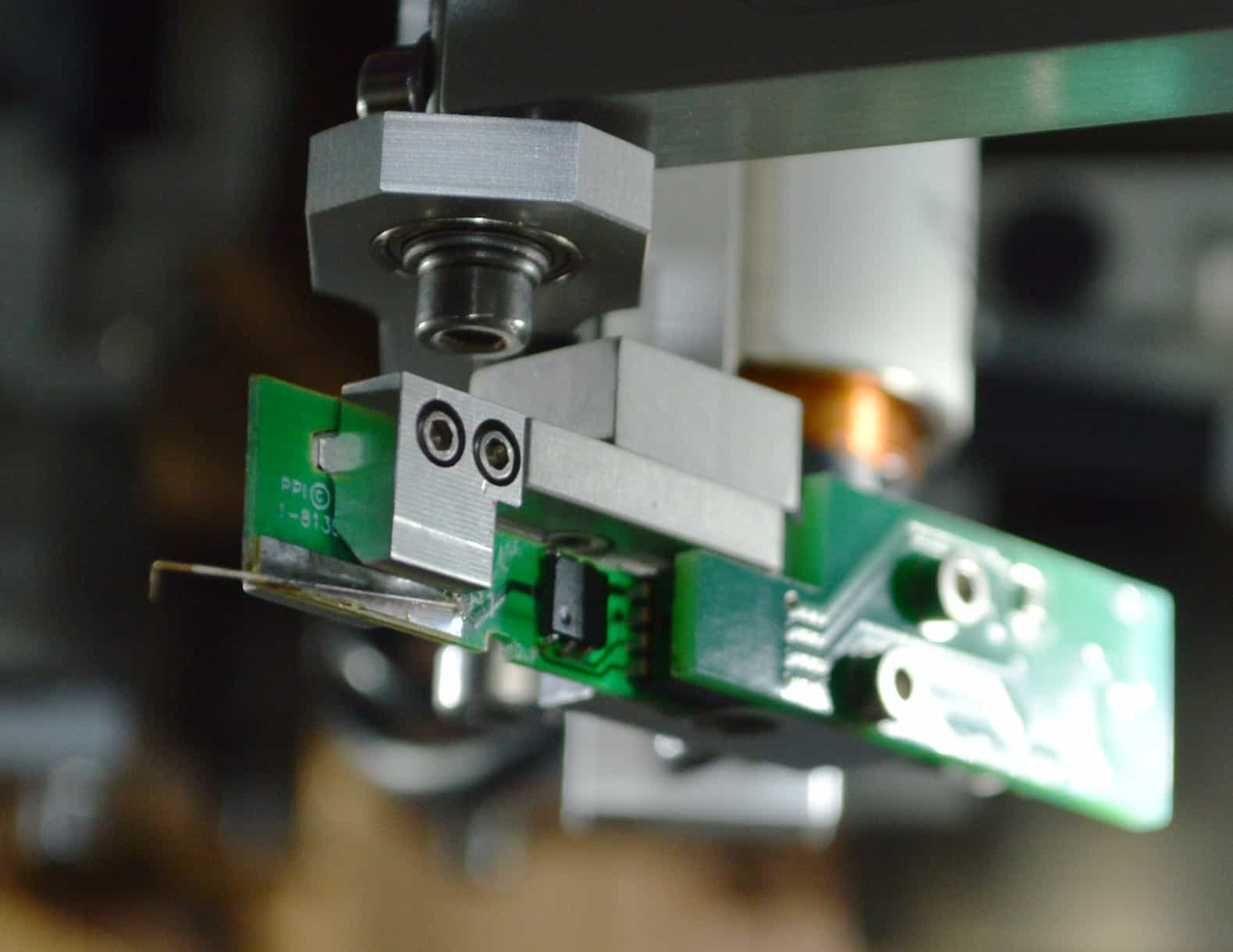

ProVia FP-C

Drilling and Cutting System

ProVia FP-C laser drilling systems provide a high peak power RF-excited CO2 . The CO2 spot size is continuously variable using a programmable zoom telescope.

System Features Include:

Request for Information

Contact PPI Systems to discuss the right solution for you.

Laser Via Drilling Systems

Datasheet

Options include autoloaders, integrated inspection microscopes, beam homogenizers, zoom telescopes, dual-head, dual-panel drilling and more..

A selection of videos including system tray loading, robotics, compact loader operation, ProVia laser processing and other automation features.

Industry 4.0 refers to a new stage in the Industrial Revolution which focuses on smart and autonomous systems fueled by data and machine learning.