iNDUSTRIES

Aerospace Component

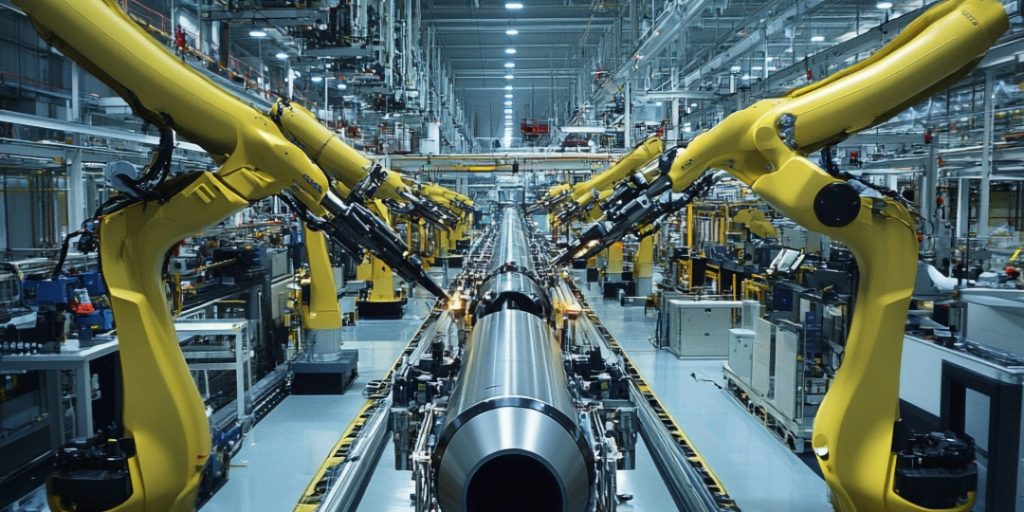

Laser drilling and trimming systems allow aerospace component manufacturers to improve performance and reduce the size and weight of components.

Laser drilling and trimming systems allow aerospace component manufacturers to improve performance and reduce the size and weight of components.

Printed circuit boards and hybrid circuits for aerospace component manufacturers have an ever-increasing demand for higher technical performance and reliability at an affordable cost. In addition, they are required to perform in severe conditions which may include extremes in temperature, humidity, vibration and impact as well as survive in harsh environmental conditions such as salt spray, blowing sand, dust, and solar radiation.

Electrical circuits are a fundamental component to aerospace engineering, controlling everything from flight control systems to avionics and engine control. They are essential for a wide range of functions including lighting, communication, navigation and other critical systems. The complexity of these circuits can vary greatly. Aerospace applications rely of the precise measurement and control of electrical parameters requiring high-precision resistors for voltage and current measurements. Accuracy is crucial for maintaining optimal performance.

Printed circuit boards and hybrid circuits for aerospace component manufacturers also have an ever-increasing demand for higher technical performance and reliability at an affordable cost. In addition, they are required to perform in severe conditions which may include extremes in temperature, humidity, vibration and impact as well as survive in harsh environmental conditions.

RapiTrim system configurations are ideal for the production of temperature sensors for a wide variety of applications including military and aerospace. Temperature sensors are used to monitor thermal conditions within engines, fuel systems and other critical components.

Weight and size limitations on avionic components require that HDI multi-layered boards are used. These have layers of circuits that are connected by laser drilled blind micro vias leaving more space for components on the board surface and facilitates unimpeded routing of signals on inner layers. The result is a much smaller board size and layer count compared with mechanical drilled PCBs, and an equivalent drop in cost. The precision and process control provided by laser solutions also ensure that the reliability of the resulting component meets the tough requirements found in aerospace manufacturing facilities.

PPI’s ProVia systems deliver the precision and flexibility to meet the demands of tomorrow’s advanced PCB materials and build-up constructions.